Carbon Plate Analysis For Performance Footwear

As an engineer and a track athlete, carbon plates are a fascinating crossover of performance and design. As part of a materials and manufacturing course, I led a project focused on understanding the role of carbon fiber plates in high-performance running shoes. These plates are engineered to improve energy return, translating material properties directly into athlete performance. By analyzing, testing, and fabricating carbon plates, I developed a deeper understanding of how engineering decisions impact footwear function.

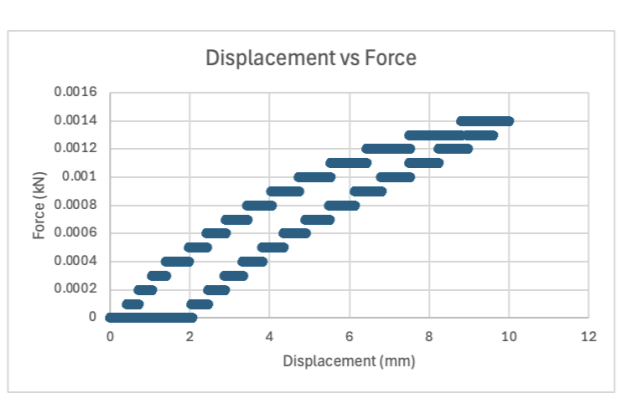

This project explored the mechanics of carbon fiber plates in running shoes and how they impact performance. I began by deconstructing a Nike Vaporfly to isolate its carbon plate, then ran Instron compression tests to measure force-displacement behavior. Using numerical integration, I calculated the plate’s energy return at about 72%, giving a clear picture of how the component contributes to running efficiency.

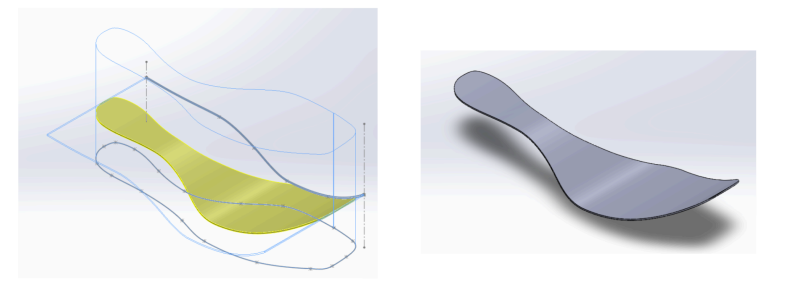

Alongside physical testing, we created a CAD model of the plate in SolidWorks and ran Finite Element Analysis. Comparing simulated displacement to real test data highlighted how boundary conditions and modeling assumptions affect accuracy—insight that mirrors the difference between lab and in-shoe performance.

To extend the study, we fabricated a custom plate using Markforged carbon fiber filament. While the unidirectional print pattern reduced stiffness, the process underscored how fiber orientation and manufacturing constraints directly shape mechanical properties. Testing our prototype reinforced the link between design choices, material behavior, and functional performance.

Through this project I built skills in product decomposition, CAD/FEA modeling, mechanical testing, and additive manufacturing—while gaining hands-on experience with the same design and material challenges faced in footwear innovation.

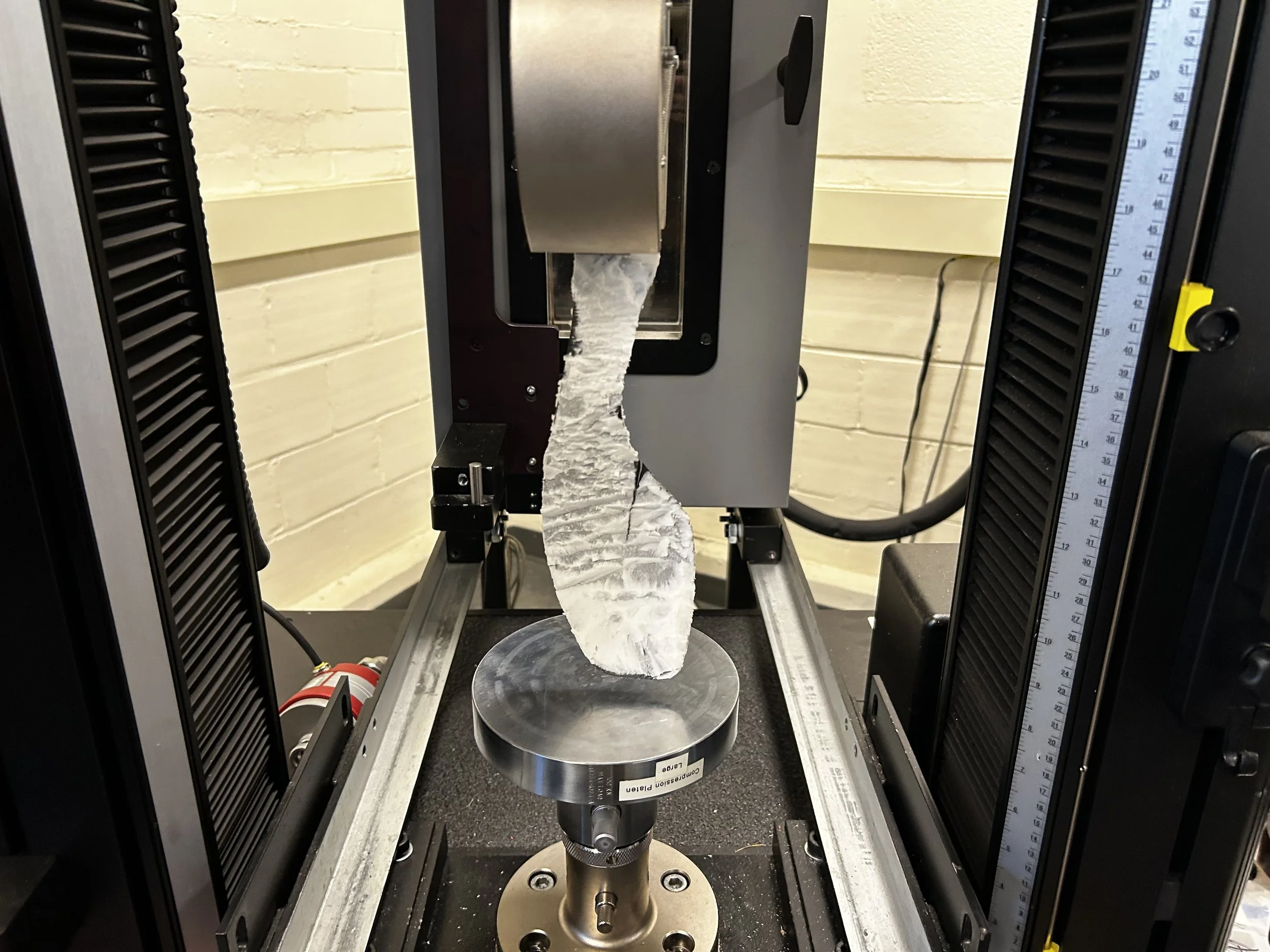

(1) Product teardown - carefully extracting the carbon plate from the foam.

(2) Product teardown - foam and plate removed from the original shoe.

(3) Instron testing the carbon plate - increasing the load and seeing how the plate reacts to force.

(4) Results from the Instron compression testing - we can find the energy return by the area under the curve during compression minus the area under the curve during decompression! We found an average energy return of ~72%.

(5) Our CAD model replicating the carbon plate.

(6) Our attempt to recreate the carbon plate using Markforged carbon fiber filament.

Skills & Knowledge Developed

〰️

Skills & Knowledge Developed 〰️

Mechanical testing (Instron compression, energy return calculation).

CAD & FEA (SolidWorks modeling, boundary condition setup, interpreting results).

Materials knowledge (carbon fiber, anisotropy, layup, durability).

Fabrication & prototyping (3D printing with composites, design iteration).

Data analysis (force-displacement curve analysis, numerical methods like trapezoidal Riemann sums).